Ironing Integrated Boiler

Color:As Required

Weight:As Required

Length:As Required

Description:

It adopts creative structure with ironing table and boiler integrated, easy operation,saving s

Description

It adopts creative structure with ironing table and boiler integrated, easy operation,saving space. Reuse of the waste steam retrieved from the iron for board heating and water heating, saves energy and protects the environment.

Main devices and functions

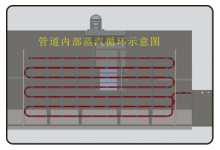

1.Board Heating: The waste steam retrieved from the iron is reused to heat the S shaped stainless pipe underneath, hence to keep the table sponge dry, decrease the humidity of the garments and shorten the time to dry up the garments. It also helps to prevent the sponge becoming mouldy and discolored due to long time humidity.

2.Water Heating : After heating the board,the waste stream goes through the S pipes and into the tank.Water temperature in the tank with the reused steam waste is increased to about 90 degree, which saves the heating time, environmental friendly.

3.Special Water Tank Design: The tank adopts drawer design for water filling, very convenient, solving the trouble to use special tools for water filling in traditional design.

4.Quiet Air Outlet: The square air duct at air outlet is furnished with silencer cotton to decrease the resonance caused by strong air, hence to deaden the noise.

5.It’s equipped with versatile casters, easy for moving.

ST-309C Ironing Integrated Boiler Main Technical Parameter

|

Model |

Power |

Rated steam Pressure |

Rated Steam temperature |

Steam Output |

Voltage |

Working Table |

Sucking Motor Power |

Machine Size |

|

ST-309C/4.5 |

4.5KW |

0.4Mpa |

151℃ |

6KG/H |

220/380V |

1530×970MM |

750W |

1530x970x1520MM |

|

ST-309C/6 |

6KW |

0.4Mpa |

151℃ |

9KG/H |

220/380V |

1530×970MM |

750W |

1530x970x1520MM |

Online inquiry

PRODUCTS

Contact Us

Phone:4000-97-98-99

Emain:www@xmstao.com

Address:65,Tong’an Section,Tong’an Industrial Ares,Xiamen, Fujian China